STATE Mfg.

Pucks

and

Tube Holders

Why use pucks?

Puck Benefits

Pucks can be designed for shrink sleeve wrapping operations.

Why use pucks?

Puck Benefits

Pucks keep the bottles clean. When bottles continuosly rub on rail systems for example, smudging and label damage can result.

Why use pucks?

Puck Benefits

Pucks keep hard to handle bottles such as Tottles upright with their nozzle openings centered within the puck for a predictable filling target.

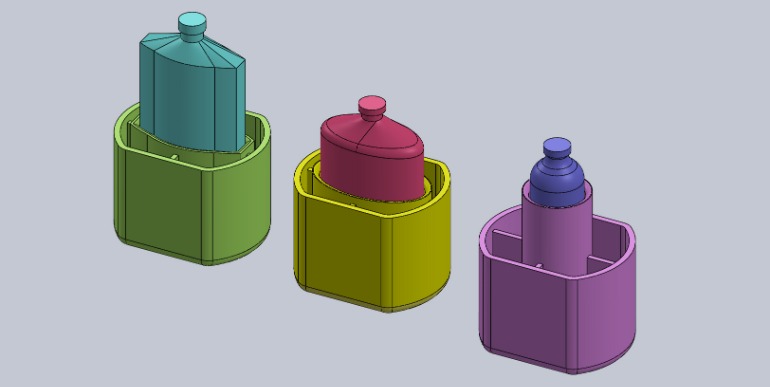

Multiple bottles with the same puck footprint

Why use pucks?

Puck Benefits

Different bottles can be run on the same filling line with little or no change over time and expense. This is because the bottles fit in a puck who's dimensional footprint is common for all bottles. The change parts are designed for use with the puck footprint, and not each bottle. So to change over to a new bottle, just change out the pucks. For contract packagers the intial start up costs for a new bottle filling project are known. This helps in providing a competive bid.

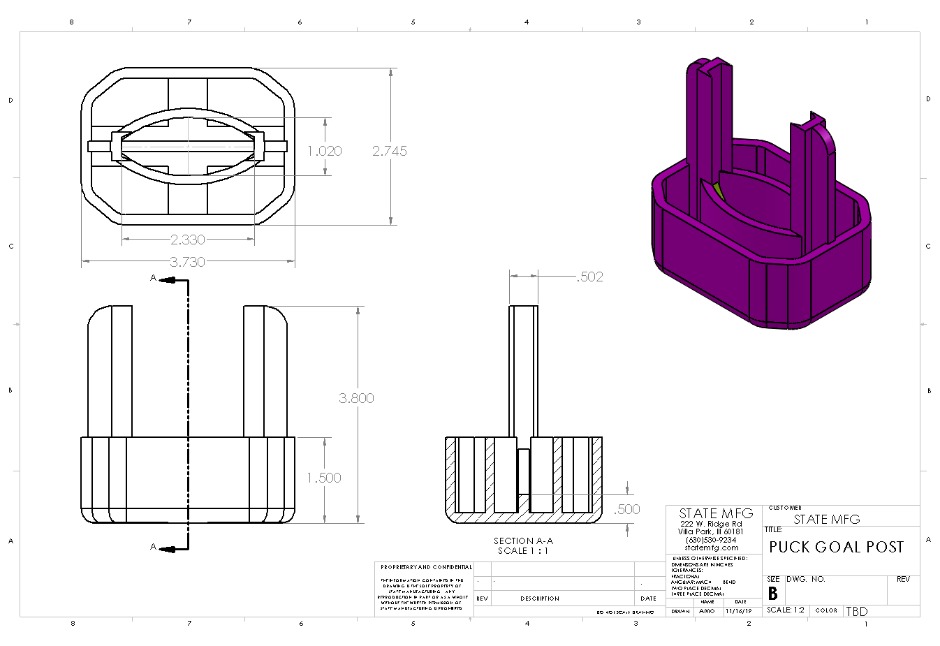

Goal Post Puck for filling, capping, and labeling

Why use pucks?

Puck Benefits

Pucks can be designed for multiple operations. For example, a Goal Post puck can be used to fill, cap, and label within one orbit of the filling line.

MSME OWNED AND OPERATED

Master of Science Mechanical Engineering

In-House 3-D design, plastic injection molding & CNC machine shop

Challenge us with your engineering request.

If you have a part you think may be difficult to produce or more economical to injection mold, don't be afraid to ask us. We may run, but we may take on the project. We love a challenge.

OUR STORY

State Manufacturing started as a patternmaking shop in 1919 by two Swedish immigrants. State quickly established itself as a high quality patternmaking shop. In the 1930z, State began manufacturing, among other machinery, top of the line disk and spindle sanders.

Before State's involvment with pucks, the original pucks were made from aluminum castings. The process started with a wood pattern from which aluminum castings were made. The aluminum castings were machined and washers were installed with screws. Known as a high quality pattern shop, State Mfg was approached in 1965 to make patterns for puck castings. State had experience in plastic injection molding from their involvment in molding parts for the agriculture industry. After some development work by State, pucks became a plastic injection molded part replacing the expensive aluminum casting process.

STATE Mfg

Circa 1923

STATE Mfg

Sanders 1937

Typical Wood Pattern

Used in the foundry industry to produce cast metal parts.

Cast aluminum Pucks

Originally made in cast aluminum. Secondary operations included machining and washer installation.

PUCK SHOTS

Aerosol Pucks

All standard sizes available. Molded with a zinc coated steel washer. Close dimensional and weight tolerances. Available on request: +/- .5 gms weight tolerance or fully encapsulated washer.

Puck Geometry

We can match the puck footprint you need for your current or future puck project.

Goal Post Pucks

Capable of filling- capping- and labeling in one orbit.

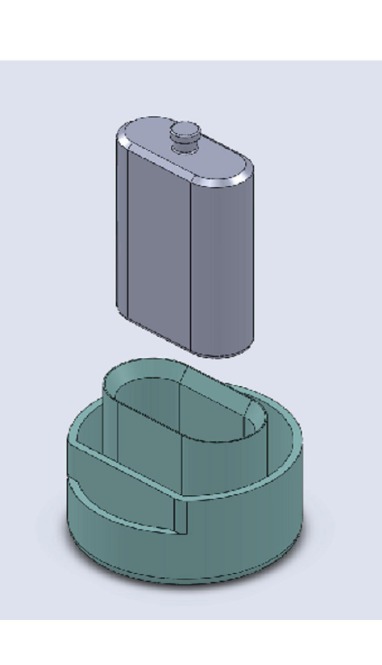

Labeling puck with fork entrance

Other Labeling Pucks

Capable of filling- capping- and labeling in one orbit.

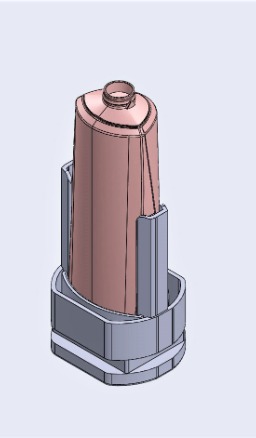

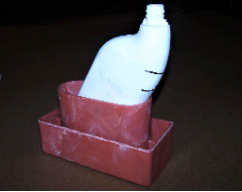

Pocket pucks

Designed to hold the filling neck upright and centered within the puck.

Tube Holder Shots

Holders for Various Tube Filling Machines

Let us know what Tube Filling machine you are using and we will work with you on making a holder for you.

If we don't have the style or size you need, we can make it for you in our in house machine shop

State Manufacturing, Inc.

222 West Ridge Road

Villa Park, Illinois

60181

andy@statemfg.com

(630) 530-9234

Come see us at the PMMI Show November 8-11, 2020 in Chicago

Booth number N-5264

To get the puck rolling send us a bottle or two. Let us know the footprint dimensions and number of pucks you need. We will generate a quote for your consideration. In the event you chose us to manufacture your pucks, we will send a few samples for your approval prior to production.